Materials and functions of solar junction box

20/05/2021At present, the market solar junction box more brands, product quality is also uneven, solar junction box in the system application of the problem is also more and more. Today Huacheng Futao from the junction box material, role, standards, and quality of several directions and we talk about the solar junction box.

1 solar junction box composition and materials

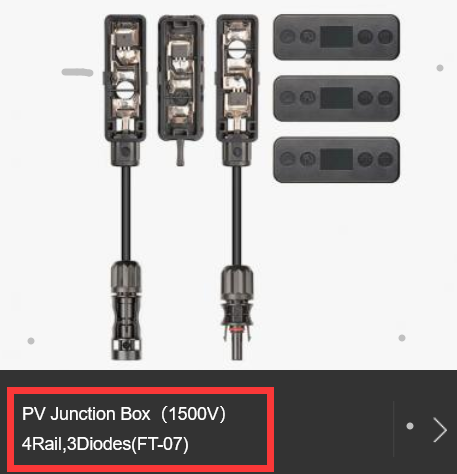

Junction box style variety, but the basic structure is the same, including the box body, box cover, connectors, terminals, diodes, etc., some junction box manufacturers designed heat sink to strengthen the box temperature distribution, there are some solar junction box manufacturers to do other aspects of the details of the design, but the total structure has not changed. Simple junction box requires at least ten kinds of materials, the performance of raw materials and service life is related to the quality of the junction box itself, so the junction box material has been highly concerned by manufacturers and photovoltaic operation and maintenance.

Raw material material.

| Name of raw material for junction box | Material |

| Base and top cover | PPO |

| Conductive block | Copper, Brass |

| Card interface | Nylon, copper |

| Diode | Schottky diode |

| Cable wire | Tinned copper wire + low smoke and halogen free cross-linked polyolefin |

| Connector | Nylon, PC |

| Rear cover and accessories | Nylon |

2 Role of solar junction box

The solar junction box has two main functions: the basic function is to connect the PV module to the load, to draw the current generated by the module and to generate power. The additional function is to protect the module lead wires from hot spot effect.

1. Connection

The solar junction box is used as a connection device to bridge the solar module to the inverter and other control devices. Inside the junction box, the current generated by the solar modules is drawn out through terminals and connectors and directed to the power-using equipment. In order to minimize the loss of module power by the junction box, the conductive material used in the junction box requires low resistance, which is smaller than the contact resistance of the lead wire of the busbar.

2. Protection

The protection of solar junction box includes three parts, one is to prevent the hot spot effect through the bypass diode, to protect the cell and the module; secondly, through the special material sealing design waterproof and fireproof; thirdly, through the special heat dissipation design to reduce the working temperature of the junction box, reduce the temperature of the bypass diode, and then reduce its leakage current to the loss of power of the module.

3 solar junction box testing standards

solar junction box in use before the test, mainly to check the appearance, sealing, fire rating, diodes and other aspects.

Breakdown of the test:

| Evaluation index | Testing Items | Test method |

| Appearance | Size, defects or not | Operation in accordance with the incoming inspection work instructions |

| Conductor and busbar tension | Mechanical performance Diode angle clamping force Conductor and junction box tension Junction box and curing tension | |

| Fire rating | Fire resistance test | Outside (the clay method is to ignite to record the extinguishing time) |

| Conductivity | Conductivity test | Use a multimeter to test whether the two ends of the wire are connected |

| Low temperature resistance | Low temperature shock | Tested according to VOE V 0126-3-2006 6.3.10 |

| Heat deformation | Baking test | 90°C , 4h, with or without deformation |

| Reliability verification | See Appendix | Test according to IEC requirements |