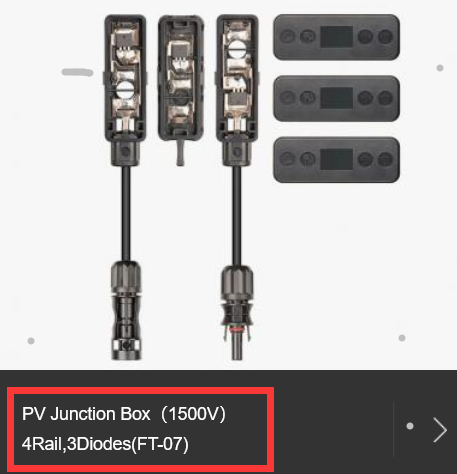

The structure and main functions of the pv junction box

26/05/2021pv junction box is to make the wire from physical impact, insect bites, electricians often use the wire tube outside the wire for protection. And in the junction of the electric wire (the connection of two wires or the corner of the wire pipe), often use the junction box as a transition. Two wire tube and junction box connected, the wire inside the tube in the junction box connected. The junction box plays the role of protecting and connecting the wires.

The role of the pv junction box is to connect the power generated by the PV module to the external wiring. Because PV modules often need to be used in harsh outdoor environments, and the warranty is up to 25 years, PV modules also have high requirements for PV junction boxes. In addition to ensure the reliability of the connection, to ensure the safety of the internal lines, photovoltaic junction box also need to have a very high anti-aging, UV resistance; to have a very high level of waterproof and dustproof, generally can reach IP67 above; use failure in more than 25 years; can withstand high current (generally require more than 20A), high voltage (generally is 1000 volts, many products can reach 1500 volts); use a wide range of temperature ( -40 ℃ ~ 85 ℃), low working temperature and a series of requirements. At the same time, in order to weaken and avoid the hot spot effect, pv junction box internal integration of diodes.

The composition of the pv junction box: general junction box by the box cover (including sealing ring), box body, terminals, diodes, cables, connectors several major components.

1.box body box cover

Box body and box cover of the base material commonly used PPO, it has a rigid, high heat resistance, non-combustible, high strength, excellent electrical properties and other advantages. In addition, PPO also has the advantages of wear resistance, non-toxic, pollution resistance, good weather resistance, etc. The dielectric constant and dielectric loss of PPO is one of the smallest species in engineering plastics, almost unaffected by temperature and humidity, and can be used in the field of low, medium and high frequency electric fields. The unmodified pure PPO has high melt viscosity and very poor processability and moldability, and cannot be molded by injection molding. In order to solve this problem, PPO can be modified by physical or chemical methods, and the modified PPO is called MPPO. hot melt MPPO is molded by injection molding machine to form the box body. The manufacturing method of the lid is the same as the box body, only the mold is different. In order to improve the waterproof performance, the box cover will have a seal made of silicone.

2.Terminal

The input terminal of the terminal is connected to the convergence bar of the PV module, and the output terminal is connected to the cable. The material used for the terminal is generally pure copper or tinned copper. Tin-plated copper, refers to the surface of a thin layer of metal tin coated copper. Tin mainly plays a role in protecting copper, to prevent copper is oxidized to form copper green affect conductivity. At the same time, the tin melting point is low, easy to weld, and good conductivity. Also use chrome-plated copper to do the terminal. (high and low voltage electrical performance), environmental performance testing (packaging vibration test, product vibration test, material flame retardant test, aging test, alternating heat and humidity test, salt spray test) can be used.

3. Diode

Diode is actually a PN junction, with the characteristics of a single conductor. Classification by use, diodes can be divided into rectifier diodes, fast diodes, voltage regulator diodes, light-emitting diodes.

4. Cable

Commonly used cables are copper or tinned copper conductors inside, two external protection, that is, polyvinyl chloride (PVC) insulation plus PVC jacket, but PVC does not meet the aging requirements, and contains halogen, chlorine gas will be released when heated, the safety is not good. Photovoltaic cables require irradiation cross-linked polyolefin in addition to the conductor (irradiation cross-linking technology refers to the irradiation to achieve the cross-linking reaction of macromolecules, so that the linear polymer into a polymer with three degrees of space network structure, so that its long-term allowable operating temperature from 70 ℃ to more than 90 ℃, short-circuit allowable temperature from 140 ℃ to more than 250 ℃, while maintaining its original excellent electrical properties, greatly (The actual use performance is improved.) Insulation plus irradiated cross-linked polyolefin sheath. Photovoltaic cable internal is a cross-sectional area of 4mm2 copper wire, if the nominal current of the PV module (less than 10 amps) to calculate, 2.5mm2 copper wire is sufficient, but taking into account the PV module often work under high temperature conditions, when the cable capacity is reduced, while the system current is relatively large, so the use of larger cross-sectional area of copper wire to ensure system safety.

5. Connector

Connector is a frequent contact with electronic engineers and technicians of a component. Its role is very simple: in the circuit is blocked or isolated between the circuit, bridging the communication, so that the current flow, so that the circuit to achieve the intended function. A pair of connectors consists of a male connector and a female connector, using PPO as the insulating material. The male connector is used for the positive terminal of the assembly and the female connector is used for the negative terminal.

6 Potting glue

Many junction boxes use silicone potting to protect their internal devices and to improve heat dissipation performance. Junction box potting adhesive is mainly based on two-component silicone. Two-component silicone is composed of A, B two kinds of glue, A type of glue is called the base glue, B type of glue is called the curing agent. When the AB class glue in accordance with a certain proportion of the mixture before use, mixed into the junction box for curing. Mixing process should be extra careful to minimize the mixing of air. Silicone potting adhesive can be cured at room temperature (25 ℃), but also can be cured by heating. Room temperature cured potting adhesives can also be heated to accelerate curing. The curing agent should be pre-mixed before use because some precipitation may occur during delivery and storage. The curing agent tends to react with moisture in the air, so extra care should be taken to avoid contact with air before use.

The pv junction box has three main functions.

1. MPPT function: through the hardware and software for each panel configuration of the maximum power tracking technology and control devices, the technology can maximize the possibility of improving the panel array of different panel characteristics brought about by the power plant power generation efficiency reduction, reduce the "barrel effect" on the power plant efficiency, can greatly improve the power plant power generation From the test results, the maximum power generation efficiency of the system can even be improved by 47.5%, which increases the investment income and greatly shortens the investment payback period.

2. Fire and other abnormal conditions intelligent shutdown function: in the event of a fire, the junction box built-in software algorithm with the hardware circuit in 10 milliseconds to determine whether an abnormality occurs, and take the initiative to cut off the connection between each block of panels, the voltage of 1000V will be reduced to about 40V human acceptable voltage to ensure the safety of firefighters.

3. The use of MOSFET thyristor integrated control technology, instead of the traditional Schottky diode. When the shadow blocking occurs, you can instantly start the MOSFET bypass current to protect the safety of the panel, while the MOSFET because of its unique low VF characteristics, so that the overall heat generation in the junction box is only one tenth of the ordinary junction box, the technology greatly extends the life of the junction box, to better protect the life of the battery.