HIT "heterojunction" Battery Technology Introduction

19/01/2020HIT is the English abbreviation of "heterojunction" cell technology, which is simply a brand new photovoltaic cell production technology. HIT technology has several advantages: high photoelectric conversion efficiency, excellent performance, large cost reduction space, and good prospects for parity internet access. As one of the battery technology solutions, HIT technology was once known in the industry as one of the candidate technologies for next-generation commercial photovoltaic production.

What is HIT?

HIT is the abbreviation of Heterojunction with Intrinsic Thin-layer, which means intrinsic thin-film heterojunction. Since HIT has been applied for a registered trademark by Japan's Sanyo Corporation, it is also called HJT or SHJ (Silicon Heterojunction solar cell).

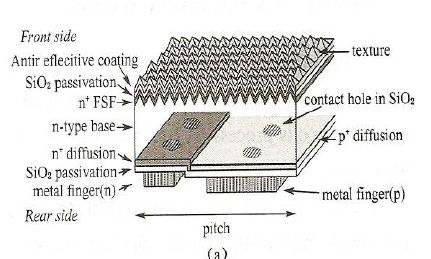

The figure below shows the basic structure of a HIT solar cell, which is characterized by a pi-type a-Si: H film (film thickness 5-10 nm) on the light irradiation side and an n-type a-Si: H film (film thickness 5- l0nm) sandwiching a crystalline silicon wafer, forming transparent electrodes and collector electrodes on the top layers on both sides to form a HIT solar cell with asymmetrical structure.

Figure 1: Schematic diagram of the HIT solar cell structure

Source: Google

2.HIT battery process

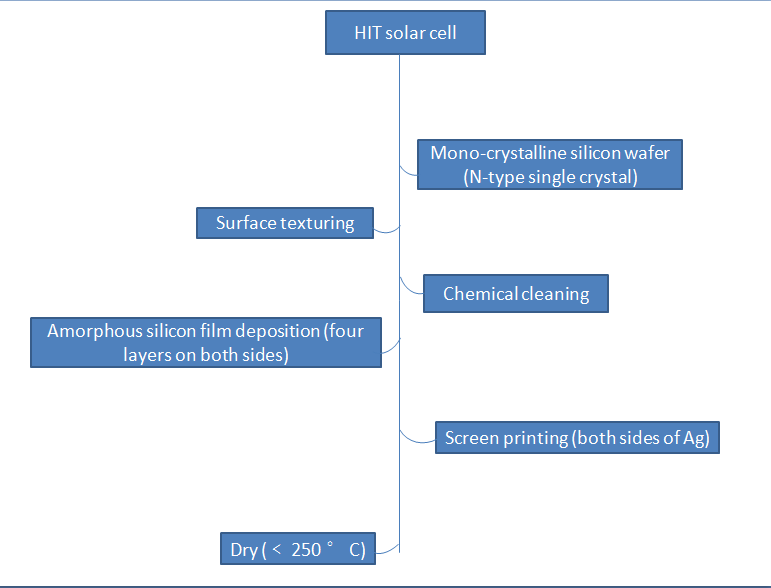

One of the great advantages of HIT batteries is that the process steps are relatively simple and are divided into four steps: texturing and cleaning, amorphous silicon film deposition, TCO preparation, and electrode preparation.

Figure 2: HIT solar cell process flow

Source: OFweek Industry Research Center

3. Advantages and characteristics

HIT batteries have the advantages of high power generation and the low cost of electricity. The specific characteristics are as follows:

(1) Low-temperature process. HIT cells combine the advantages of low-temperature (<250 manufacturing="" of="" thin-film="" solar="" thereby="" avoiding="" the="" use="" traditional="" high-temperature="">900 ° C) diffusion processes to obtain p-n junctions. This technology not only saves energy, but the low-temperature environment enables a_Si: H-based thin-film doping, forbidden bandwidth and thickness to be controlled more accurately, and it is easy to optimize the device characteristics in the process; during the low-temperature deposition process, the single product silicon wafer is deformed small, so its thickness can adopt the minimum value (about 80μm) required for the background light-absorbing material; meanwhile, the low-temperature process eliminates the performance degradation of the silicon substrate in high-temperature processing, thereby allowing the "low quality" crystalline silicon or even polysilicon to be used as a substrate.

(2) The double-sided battery. HIT is a very good double-sided battery. There is basically no color difference between the front and the back. The advantages of backside power generation are obvious.

(3) High efficiency. At present, the laboratory efficiency of HIT batteries has reached 23%, and the battery efficiency of commercially available 200W modules has reached 19.5%.

(4) The high-stability HIT battery has good light stability. Theoretical research shows that the Staebler-Wronski effect is not found in amorphous silicon films in amorphous silicon films / crystalline silicon heterojunctions so that similar solar energy to amorphous silicon does not occur. Battery conversion efficiency declines due to light; HIT batteries have good temperature stability. Compared with single crystal silicon batteries, the temperature coefficient of -0.5% / ℃, the temperature coefficient of HIT batteries can reach -0.25% / ℃, making the battery output well even under light-heating conditions.

(5) One of the most important problems that plague crystalline silicon solar cells without photoinduced attenuation is photoinduced attenuation, while HIT cells have no natural attenuation, and even increase the efficiency to a certain extent under the light. Shanghai Microsystems does HIT photoinduced attenuation during the experiment, founding that the HIT battery conversion efficiency is increased by 2.7% after light exposure, and there was no attenuation phenomenon after continuous light exposure.

(6) The symmetrical structure is suitable for thinning. HIT cells' perfect symmetrical structure and low-temperature process make them ideal for thinning. After a lot of experiments, Shanghai Microsystems found that the average efficiency of the silicon wafer is almost unchanged within the range of 100-180 μm. The 100μm-thickness silicon wafers have achieved a conversion efficiency of more than 23%, and 90μm silicon wafers are currently being prepared in batches.

(7) The thickness of the low-cost HIT battery is thin, which can save silicon materials; the low-temperature process can reduce energy consumption and allow the use of cheap substrates; high efficiency allows the area of the battery to be reduced under the same output power, thereby effectively reducing the cost of the battery.